UV Curable Glues

UV Glue Curing Unleashes Indestructible Bonds

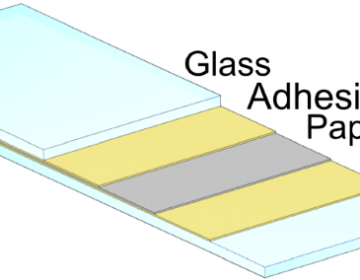

UV Glue Curing, often referred to as liquid glue, employs a remarkable polymer compared to a conventional adhesive. This polymer, often in silicon, epoxy, polyurethane, or other forms, transforms into a transparent solid when exposed to UV light. The UV wavelength triggers a photochemical reaction that instantly hardens the polymer. In most scenarios, a mere three-second exposure to UV light solidifies the polymer, though specific applications might recommend a ten to fifteen-second exposure for optimal bonding. Compared to other curing methods, this speedy process maximizes efficiency across a range of adhesion applications.

UV Glues are being preferred compared to conventional alternatives such as heat or chemical curing. Heat or drying methods rely on evaporation, which can be inconsistent and time-consuming. Chemical treatments can be expensive and expose workers to hazardous substances. In contrast, UV glue curing is rapid, consistent, and instantly hardens the surface without harmful chemical exposure.

Powerful Photochemical Reaction with UV Glue Curing

UV glue does not harden until exposed to UV light, preventing accidental bonding. This precise hardening targets only the intended bonding area, avoiding unintended sticking. The photochemical reaction occurs within a specific range of UV wavelengths, typically between 240 nm to 270 nm and 350 nm to 380 nm.

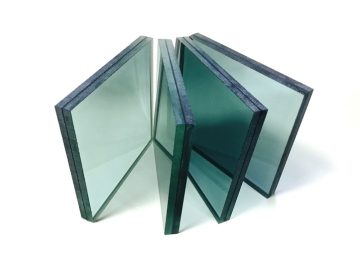

In certain cases, multiple layers can be applied to achieve a stronger, unbreakable bond. This process works across a wide array of substrates, including plastic, glass, metal and even glass-to-glass bonding. The adaptability to three-dimensional parts accelerates curing, saving time and resources.

Automotive assembly lines often use UV glue curing for interior parts like buttons or knobs. The UV process provides an impeccable gloss finish that resists scratching, staining, and fading, enhancing the visual appeal of products.

A key advantage of UV curing is the transparent finish, allowing multiple layers for added strength. Sanding down the finish creates an invisible “liquid plastic” bond. The finished surface can be painted or stained, providing endless application possibilities.

The benefits of UV glue curing are evident in increased productivity. Quick curing speeds to boost efficiency and profitability. The instantaneous bonding during the manufacturing process saves time and labor compared to chemical treatments or drying stations. UV curing stations have a compact footprint, requiring less space than alternative curing methods. The efficiency and high yield contribute to a rapid return on investment.

Consistent and improved quality is a major advantage of UV glue curing. Unlike drying methods that lead to volume loss, UV curing maintains consistency. This results in reduced scrap, improved bonding quality, and enhanced scratch resistance and gloss. UV glue curing strengthens bonds while offering an eco-friendly and chemical-free process.

Versatile Applications of Curing Lamps

UV glue curing finds applications across commercial, industrial and even residential domains. It is used in areas such as:

- Decorative applications on plastic and glass

- Graphic arts and printing

- Electronics

- Automotive and boating

- Plumbing

- Manufacturing processes

Key Characteristics of MMSC UV Glues

- Single-Component Solution

- Variable Viscosity

- UV-Cured Bonding, activated only by exposure to UV light source

- Instant Adhesion

- Optical Transparency

- Material Compatibility: UV adhesives are frequently employed to bond glass or hard plastics (e.g., PMMA, PVC) to similar materials or different substrates (metal, ceramics, etc)

Curing Time Profile of MMSC UV Glues

- Polymerization generally completes within 10 to 30 seconds of UV exposure.

- Factors influencing polymerization time include UV lamp spectrum, distance between the lamp and adhesive, glue thickness, and material properties.

Application Guidelines

- Clean surfaces for assembly.

- Apply UV glue without introducing bubbles.

- Align surfaces without creating tension.

- Remove excess glue using a lint-free cloth.

- Initiate polymerization by exposing it to UV light.

Choosing the Right UV Adhesive:

- Select based on material compatibility, required strength, and intended use.

- Ensure the UV lamp’s spectrum corresponds to the chosen adhesive.

- For areas inaccessible to UV light, consider multipurpose adhesives with alternative curing methods.

- For hard-to-reach spots, opt for ultra-fluid UV adhesives with capillary action.

Sample Applications:

- Attaching ornaments to glass

- Fixing metal handles to glass doors

- Bonding metal frames to glass panels

- Museum display cases

- Mounting displays and POS accessorie

Industrial Applications:

UV adhesives are ideal for fast production cycles, with benefits including uninterrupted production steps and easy integration of quality control. They find use in various industries such as POS/POP, automotive, electronics, medical, telecommunications, furniture, and decoration.